Energizing the future of electric vehicle transportation

Xiangyang Dong received an NSF CAREER Award to explore additive manufacturing of electric vehicle batteries

Whirring down the streets, electric vehicles, or EVs, are becoming more popular as the world shifts to climate-friendly transportation alternatives.

Xiangyang Dong

The U.S. Department of Energy has found that EVs combat the climate crisis by mitigating greenhouse gas emissions and improving air quality, resulting in a reduction in pollution-related health concerns. The rechargeable batteries used in EVs are essential components in the transition from the use of internal combustion engines in vehicles.

Xiangyang Dong, an associate professor of manufacturing engineering in the School of Manufacturing Systems and Networks, part of the Ira A. Fulton Schools of Engineering at Arizona State University, says due to current barriers such as charging infrastructure, heightened performance and energy efficiency will be essential to solidify the widespread adoption of electric vehicle transportation.

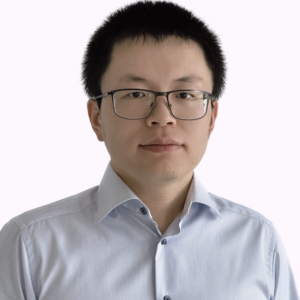

Existing research focuses on enhancing the chemistry and energy density of rechargeable batteries’ individual cells. Improvements to the protective mechanical battery enclosures, which reduce vehicles’ overall efficiency, have yet to be fully developed.

For his work to improve battery designs, Dong has received a 2024 National Science Foundation Faculty Early Career Development Program (CAREER) Award. His approach will explore the use of continuous carbon fiber reinforced composites to create a new material that can support heavy structural loads while successfully storing electrical energy. The materials that make up the structure of vehicles’ bodies will, in and of themselves, serve as the vehicles’ batteries, resulting in a decrease in mass and volume and an increase in energy storage efficiency.

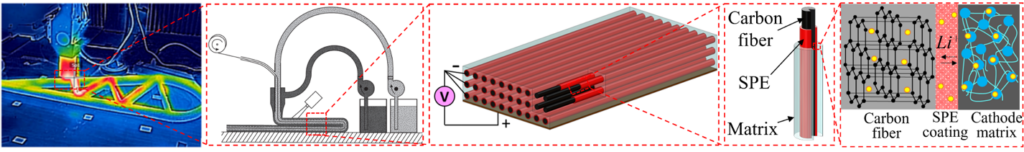

A diagram showing an alternative design where an electric vehicle or aircraft’s structure also serves as its battery. This approach would integrate energy storage and load-bearing capabilities to create a multifunctional material. Graphic courtesy of Xiangyang Dong

With more than the $600,000 in project funding, Dong will use a bottom-up strategy to transform continuous carbon fibers into 3D structural batteries, allowing for a variety of uses.

A diagram showing the scalable additive manufacturing process of multifunctional materials integrated with carbon fibers into a 3D structural battery composite, where each single carbon fiber is functionalized by coating materials and acting as a small battery cell. Graphic courtesy of Xiangyang Dong

“The key here is to achieve high surface contact area and bonding between single carbon fiber and cathode materials within 3D structural batteries,” Dong says.

The new manufacturing method begins with a single functionalized fiber, or a fiber that has been chemically or physically modified to have specific properties, that serves as a versatile building block. The new 3D material composite will then be analyzed and implemented for a variety of structural functions.

If successful, the composite will extend the operational range of electric vehicles and achieve massless energy storage, resulting in weight reductions and enhanced energy efficiency.

The insights gained from this research will drive the advancement of next-generation lightweight materials, catering to the growing demand for EVs.

Dong’s work will also incorporate education and outreach activities.

“Throughout this project, I aim to motivate engineering students to pursue graduate study and broaden participation in clean energy manufacturing,” he says.

Beyond cars, this technology has the potential to transform complex systems including aircraft, spacecrafts and even ships. A deep understanding of this new manufacturing process has potential to create other multifunctional structural composites for applications such as sensing, health monitoring, energy harvesting and morphing, a process involving changing the shape of a structure to adapt to its surroundings.

“This project will advance the design and fabrication of next-generation lightweight multifunctional materials, paving the way for innovative approaches in the deployment and decentralization of high-performing energy storage units,” Dong says.