Volvo will slide a skateboard under its electric XC90 SUV

Volvo’s first few fully electric models, the Polestar 2, the Volvo XC40 Recharge, and the 2022 Volvo C40 Recharge that was revealed Tuesday, were all developed on the same platform—one that was originally designed for internal combustion engines and fuel tanks, but adapted for the fully electric models.

However Volvo’s chief technical officer, Henrik Green, noted in a Tuesday interview with Green Car Reports that they have a production advantage versus some dedicated electric cars: “We can build those vehicles in the production systems where we build other CMA vehicles such as the XC40—non-pure-electric—today,” he said, referring to how the C40 Recharge and XC40 Recharge will both be built alongside the XC40 at Volvo’s plant in Ghent, Belgium.

2021 Volvo XC40 Recharge

In these models, a T-shaped battery has been a limiting factor affecting cabin space compared to some of their EV rivals. Shoppers who opt for the South Carolina–made XC90 Recharge—or the all-electric version of the next SUV that might also be called XC100—that’s on the way in 2023 or 2024 won’t encounter such compromises, Green suggested.

The South Carolina plant, which will include a locally built battery pack, will be ready to easily flex between hybrid and pure electric versions of the XC90—and perhaps other models—to follow the market demand in the U.S. between the hybrid and the pure electric as it changes through the life cycle of that vehicle.

Volvo Cars North America CEO Anders Gustafsson referred to the brand’s targets for 50% electric by 2025 and all-electric by 2030, and said “that will be in line with South Carolina.”

New Volvo XC90’s modular SPA platform

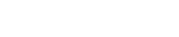

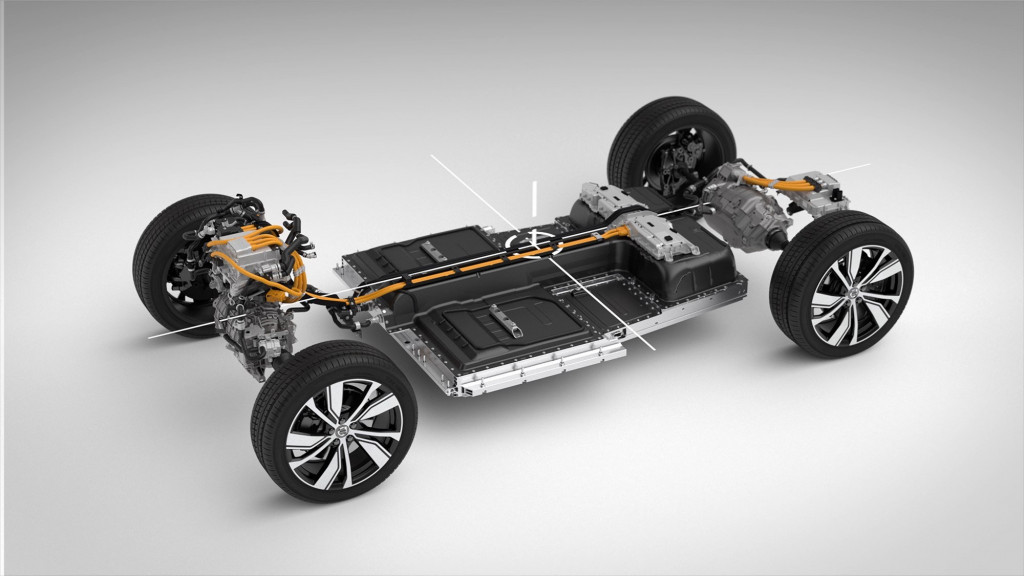

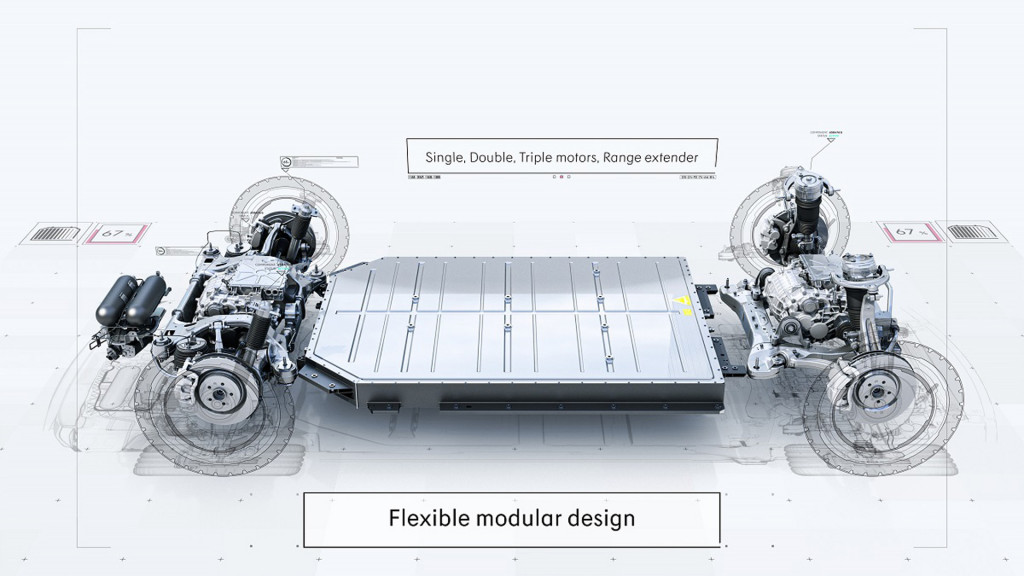

To allow the flat floor, flat battery pack, and some of the advantages of fully electric vehicles, it’s developing its next-generation platform for large and mid-size vehicle, SPA2, with a unique solution: essentially build two completely different, unique floor assemblies for the vehicle.

“One floor is built around the flat battery with an e-machine in front and rear, very much the skateboard approach that you see pure electric vehicles are built on today,” said Green. “And there is another floor which is completely different, built with a combustion engine in the front, the prop shaft, an exhaust system, a fuel tank in the rear.”

2018 Volvo S90, V90, XC60 and XC90 T8 Twin Engine

“Now those two floors will be produced in parallel on separate lines,” said Green. “However, those floors have exactly the same interface to the rest of the vehicle, so that we can fit an XC90 top hat on top of the hybrid floor or on top of a pure electric, fully optimized floor.”

According to Green, it’s the solution to “a quite complex puzzle” it needs to manage during a transition period, at its most challenging around 2025 when it sees a 50/50 mix. It lets Volvo build a competitive fully electric vehicle, as it satisfies a legacy market they can’t immediately abandon. And it allows a lot of flexibility for the SPA2 factories—to mix production between plug-in hybrid and pure electric depending on where demand is.

Not designing the two versions to be built side by side from the start, Green added, that would put Volvo in “a complicated situation, purely industrial wise if we would have a completely separate architecture.”

Geely SEA (Sustainable Experience Architecture) modular EV platform

Volvo will be moving to dedicated electric platforms eventually, Green noted, though, and the first vehicle to do that will be a smaller, urban electric car based on the global Sustainable Experience Architecture (SEA) developed by its parent company Geely.

“In this case we’re looking at a quite small vehicle…that gives us the opportunity to enter a segment with smaller vehicles than would be practically or physically viable on our own architecture,” he said, hinting that with EV platforms, smaller certainly doesn’t mean less technologically advanced.