Magna’s eBeam can help automakers turn any truck electric

Fully electric full-size pickups are one of the next big growth areas in the automotive market, for individuals and fleets alike.

With a solution from the supplier and mobility technology company Magna, automakers might be able to produce more electric trucks—or a wider range of them—sooner.

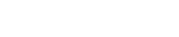

Called eBeam, and billed as “a game-changer for pickup truck electrification,” the modular solution works for EVs and hybrids and packages critical drive components within existing truck frame rails, while preserving the original load floor, towing capacity, and other capability. The assembly serves as a solid beam rear axle.

Magna eBeam propulsion system for electric or hybrid trucks

It tackles a potentially daunting barrier that traditional automakers encounter in electrifying their trucks: that using off-the-shelf electric drive components sometimes requires a redesign of some of the expensive core components of their trucks, including suspensions, chassis, and braking systems.

That essentially means that, without a cohesive solution like this, they need to make two trucks, upping the price and limiting manufacturing flexibilities.

“What we’re developing is something that would fit into an existing chassis or an existing platform,” said Sherif Marakby, VP of R&D for Magna, speaking to Green Car Reports earlier this year. “Which really helps because depending on the volumes we can scale up or down and we don’t have to change the platform.”

Magna eBeam propulsion system for electric or hybrid trucks

Magna previewed eBeam in January at CES, but on Thursday it outlined three layouts for the system: one with a single electric motor, another with a single motor and a 2-speed gearbox, and another with a twin-motor setup including torque vectoring. Power ranges from 120 to 250 kw, or 161 to 335 hp.

EBeam works with leaf-spring or coil-spring layouts and could be a good solution for electrifying the solid-axle light commercial trucks that often share some of the same components. It might also allow startups to use an existing pickup truck platform for an all-electric truck.

“We know axles are core elements of a truck’s strength, and we are excited to have developed the first significant improvement to the solid beam axle in over 100 years,” said Tom Rucker, president of Magna Powertrain, in a release accompanying the announcement.

All-electric or electrified powertrains are going to be about half of the market by 2030, the company believes. But how we get there isn’t yet obvious, and to satisfy the different wants and needs of various vehicle makers it’s come up with a building-block approach that was made possible through its joint venture with LG Electronics, which was announced in December.

2019 Jaguar I-Pace

LG Electronics already played an important development role in the drive systems for the Chevrolet Bolt EV and Jaguar I-Pace, and Magna affiliate Magna-Steyr, which will build the Fisker Ocean, builds the I-Pace. The joint venture has about 1,000 engineers already in place and working on electric motors and inverters, with a company-wide mission to integrate them within full powertrains.

For that, Magna has laid out a choice of motors, inverters, and layouts. “Every OEM, every new entrant has a different requirement, whether it’s the power level of the motors and the inverters or how it’s packaged—even where it’s packaged,” said Marakby.

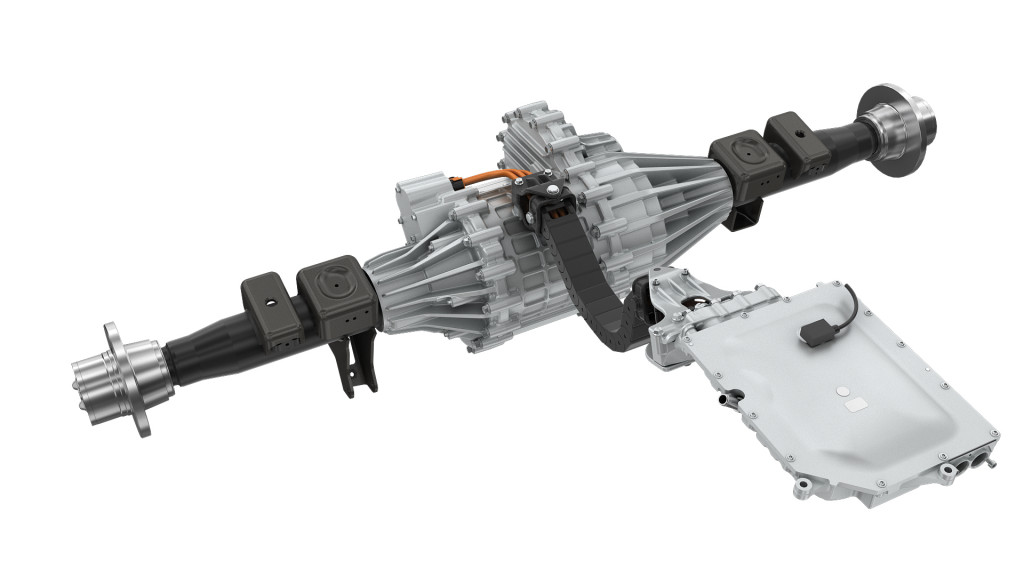

2022 GMC Hummer EV

Last month, Magna announced that it will build battery enclosures for the 2022 GMC Hummer EV at a new Magna Electric Vehicle Structures plant in St. Clair, Michigan. At CES, the company also showcased its work toward the “lightweighting” of EV battery packs, with aluminum and composite battery trays and cases capable of shedding precious pounds.

[embedded content]